Metalworking and Processing

Product solutions, a pillar in quality, accuracy and price

By constantly renewing and actively searching for the best and most cost efficient solutions in the field of metalworking and machining, we can serve you optimally. With over 25 years of experience, we are the specialist in custom work and precision mechanical production. We apply innovative techniques, which means we can make almost any part.

Share your design, the annual expected purchase quantity, delivery and packaging wishes and any target price with us and we will send our quotation within 48 hours .

Our production techniques

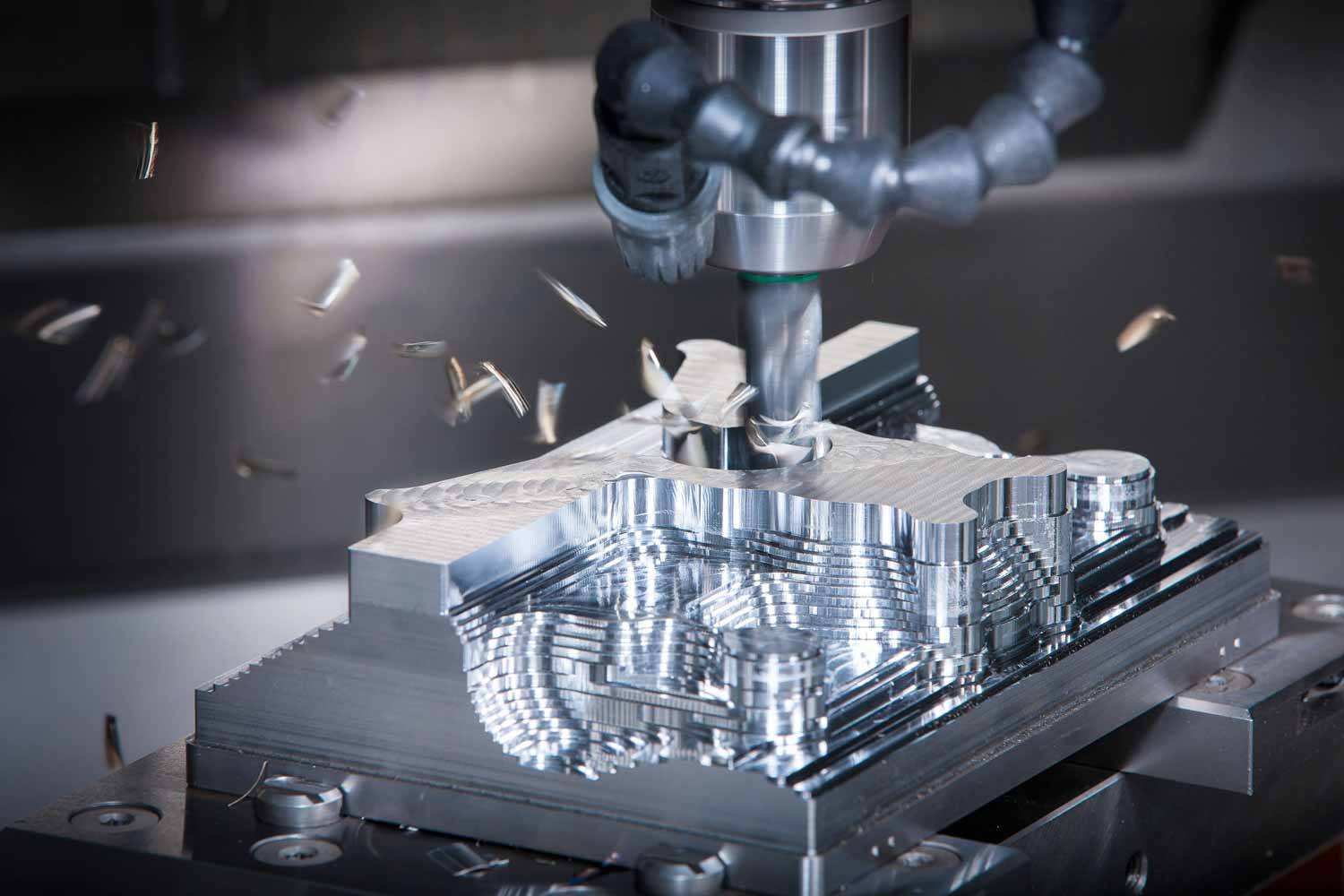

CNC- and conventional controlled milling

Maximum stroke X: 1250 mm

Maximum stroke Y: 650 mm

Maximum stroke height: 600mm

Maximum accuracy: 0,003mm

Particulars: up to 6-axis operations possible

CNC- and conventional controlled turning

Maximum diameter: 800 mm

Maximum length: 2000 mm

Maximum accuracy: 0,002 mm

Particulars: Automatic staff transfer

CNC Lasercutting

Maximum cutting range: 3500x2000mm

Maximum thickness of (casted) steel: 25mm

Maximum thickness of stainless steel: 20mm

Maximum thickness of aluminum: 15mm

CNC Tube and Pipe Lasercutting

Maximum cutting range: 6500mm

Maximum thickness: 10mm

Round pipes, tubes, L- and U-shaped profiles and flat strip

Manual or CNC-controlled folding

Simple and complex folding

Mold formation is possible

Maximum thickness: 35mm

Maximum setting range: 3000x1500mm

Maximum accuracy: 0.05mm

CNC watercutting

Maximum cutting range: 2000x1500mm

Maximum thickness: 200mm

Pressure: 4500bar (up to 1000km/h cutting speed)

Almost any material is possible

With and without abrasive

Casting

Simple and complex (die)casting

Maximum mold size: 600x600mm

Many types of material possible

Ideal for a large order volumes

CNC controlled punching

Maximum punching range: 3500x2000mm

Maximum material thickness: 8mm

Maximum accuracy: 0.02mm

Assembly

Partial- or complete assembling of your product

Assembly line with a maximum of 10 employees

Maximum weight: 10kg

Maximum dimensions: 600x600mm

MIG/MAG Welding

Manually or robot-driven welding

Simple and complex welding work

Maximum welding range: 6000mm

Our finishing techniques

Finishing techniques we can offer for your product include:

(hard) anodizing, oxidizing, powder coating, chrome plating, galvanizing, galvanizing (nickel plating),

polishing, sand and pearl rays, deburring, drumming and laser engraving.

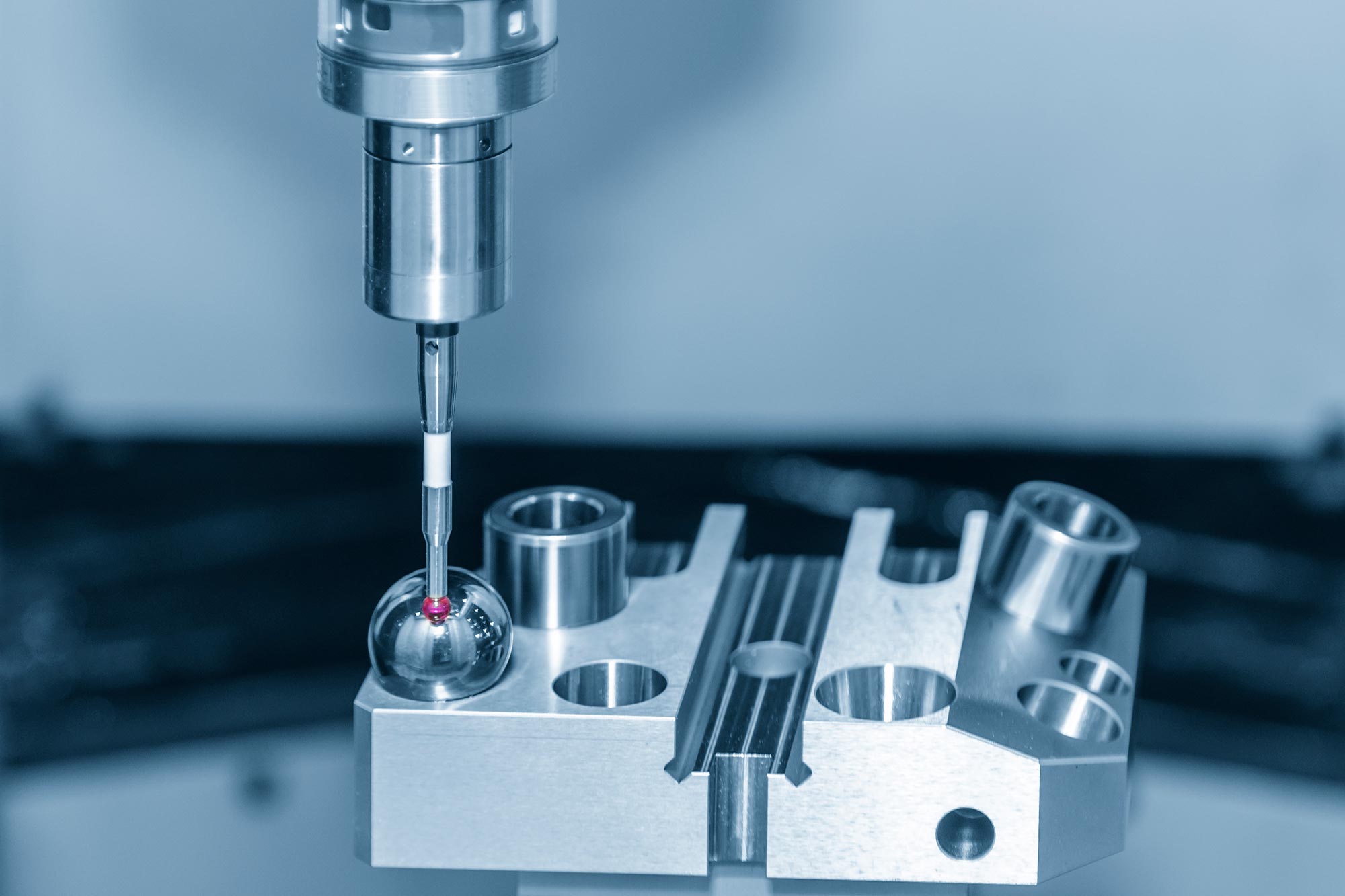

Quality without compromise

We check the production drawings completely before production.

Measurements and tolerances are accurately measured during the production process.

Upon completion of the product, it will receive a final check for damage or impurities.

Only when your product meets all quality requirements is it sent.

More possibilities

3D- printing

We can print your part in 3D. This gives you a realistic (scale) model of your product.

Choice of material

We produce your part in almost any desired material type; from steel, stainless steel, aluminum to non-ferros and plastics.

If you still have doubts about the right choice of materials, our engineers are ready to advise you.

Prototyping and laser engraving

We naturally offer prototypes to check quality and fit.

To personalize your product, we can also laser engrave your logo or image.

Batch volume and assembly

We can produce both small and large series. In addition, assembly of your product is also possible.

Machinepark

The high and consistent quality that Product Solutions can offer is achieved with the help of the most advanced production machines and measuring techniques. Thanks to optimum cooperation between our engineering department and specialists, no challenge is too big for us.

The machinery to which Product Solutions has access includes:

Lathes

2x DMG Mori NLX 2500, 3-axis turning combination

2x OKUMA LT2000EX, 3-axis turning combination

1x HAAS ST-10-V, 2-axis turning combination

4x Miyano BNE 42S, 5-axis turningcombination

3x Miyano 34T, 3-axis turning combination

2x Tsugami B0206, 6-axis turning combination

2x Citizen B12, 2-axis turning combination

4x Helong HL-46FY-DT, 4-axis turning combination

Milling machines

1x DMG Mori DMF 180/7, B-axis milling combination

2x OKUMA GENOS M460-VE, 5-axis milling combination

1x OKUMA MB-5000HII, 5-axis milling combination

2x OKK VM-5III, 5-axis milling combination

1x HAAS UMC-750SS, 5-axis milling combination

2x HAAS VF-9/40, 3-axis milling combination

4x HAAS VF-2, 3-axis milling combination

2x HAAS VF-2SS, 3-axis milling combination

2x HAAS DT-1, 3-axis milling combination

3x Sunmill X5-320, 5-axis milling combination

6x Sunmill JMV-850, 3-axis milling combination

1x FEELER NBP-1100A, 3-axis milling combination

4x Litz TV-500, 4-axis milling combination

Laser cutting machines

1x Trumpf Trumatic HSL 2502 C

1x Amada LC 2512-1AJ

2x Amada LCG 3015

1x Adige LT8 – 3,5KW

1x Adige LT8.10 Fiber – 4KW

1x Adige LT Fiber – 3KW

Water cutting machines

1x JetMachining Center OMAX 80

1x MAXIEM 1530

Bending machines

2x Harsle 160T/3200

1x Trumpf Trubend 5230 (CNC)

2x JFY hpr-10031

Punching machines

2x Nisshinbo HIQ 1250 (CNC)

1x AMD-SE2510 (CNC)